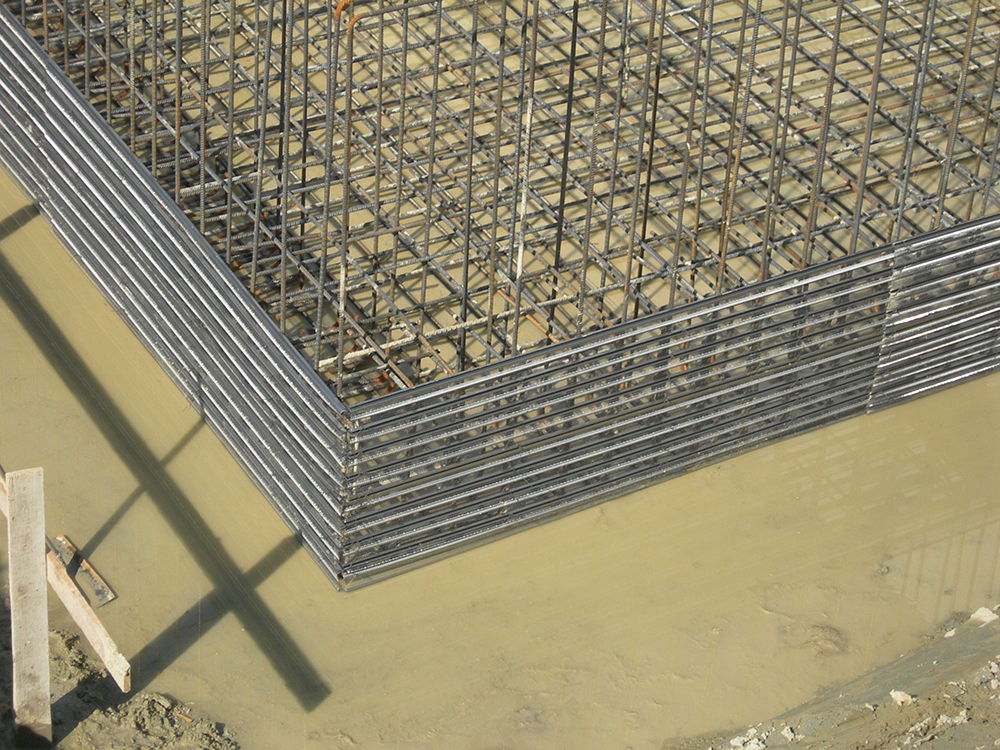

Ready for pouring. Zero waste. Maximum efficiency.

It completely replaces traditional wooden formwork and eliminates the need for stripping operations. Once installed, QuickJet® stays in place.

Why QuickJet®

Lighter and easier to handle: lower weight, reduced bulk, and easy to transport.

No storage required: order as needed, eliminating storage management.

Zero waste and cleanliness: no panels disposal or cleaning.

Eco-friendly and safe: reduces environmental impact and improves safety on site.

Extremely versatile: suitable for foundations, vertical structures, and special solutions.

Flexible in use: follows the shape of the reinforcement, even in curved structures or those with complex geometries.

Minimum coverage guaranteed: 2.5 cm of reinforcement coverage, compliant with regulations.

No need to return to the construction site for dismantling.

The geometry and thickness of QuickJet® sheets increase the rigidity and strength of the structure, minimizing the need for additional reinforcement in the formwork.

The sheets are available in different formats and modular sizes, making them suitable for use in all types of projects.

QuickJet® reduces the work required to install formwork and does not need to be removed.

QuickJet® minimizes waste.

The galvanized sheets are lightweight and easy to transport and store.

The reduced labor and time required to prepare disposable formwork represent a significant economic advantage for construction companies.

QuickJet® benefits

QuickJet® technical characteristics

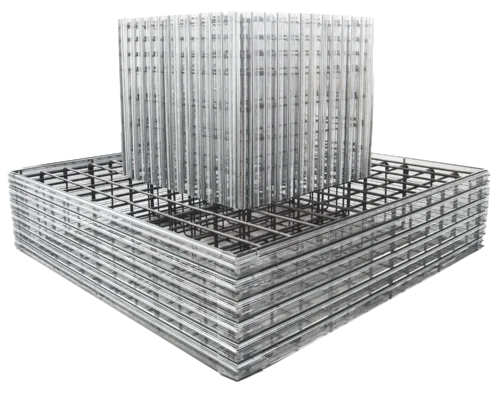

The QuickJet® system is based on a set of galvanized metal sheets with a thickness ranging from 0.4 to 0.5 mm, a length of 2 meters, and modular heights increasing in 10 cm steps—from 20 to 60 cm.

The basic elements can be placed side by side to obtain multiple sizes compared to the standard ones, or they can be partially overlapped to obtain different sizes without having to make cuts and consequently dispose of waste. They are secured to the reinforcement using simple metal ties.

The QuickJet® structure consists of ribs, which strengthen and stiffen the formwork, and lighter sections, which are cut by stamping and stretching. In addition to making the element more flexible and lighter, they facilitate binding to the reinforcement and significantly reduce the pressure exerted by the concrete casting inside the formwork.

QuickJet® is both reinforcement and disposable formwork, so there is no need for the formwork dismantling and waste disposal operations typical of traditional construction systems. It is also possible to pre-assemble the disposable formwork together with the reinforcement in the factory and then transport it to the construction site, saving time and labor costs.

Technical specifications

Standard length: 2 m

Thickness: 0.4 - 0.5 mm

Available heights: 20 cm, 30 cm, 40 cm, 50 cm, 60 cm

Packaging: pallets of 125 sheets, wrapped in polyethylene

Available accessories:

Ties (short and long)

Corner pieces and spacer bars, on request

Technical specifications manual

Main installation methods

QuickJet® adapts to different construction site situations thanks to its flexibility. The main installation methods are:

- Ribs facing inwards: these act as spacers and provide a coverage of approximately 2.5 cm from the reinforcing bar

- Ribs on the inside with additional spacers: for greater separation between the reinforcement and the formwork (up to 5 cm)

- Vertical ribs: this method allows the formwork to easily follow the shape of the reinforcement without the use of corner elements

- Horizontal ribs: requires corner elements to be placed on top of the base for a precise closure

- System warranty: QuickJet® is only guaranteed if all ribs are connected to the reinforcement and the fasteners are spaced at a maximum of 50 cm apart.

Phone

Tel: +39 02 95361185

Locations

Legal and Operational Headquarters:

Via G. di Vittorio, 25/27

25033 Cologne (BS) - Italy

Plant:

Via dell'Industria, 7, 20060

Vignate (MI) - Italy

amministrazione@quickjet.it

ordini@quickjet.it